By Application |

← |

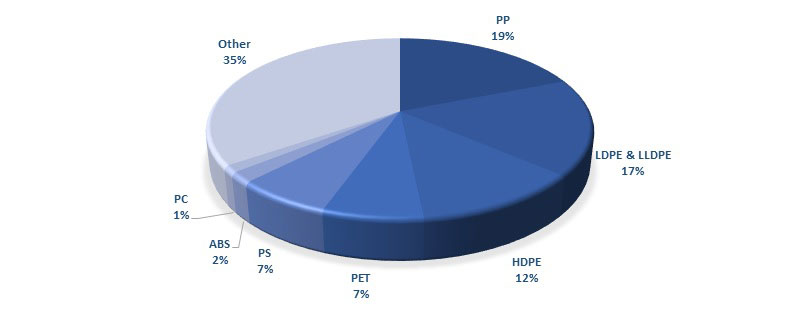

Overall demand for plastics in the EU in 2015 was 49 million tonnes. The pie chart below depicts this consumption by type of plastic.

Plastic can be processed in a number of ways:

Injection moulding - molten plastic is injected into mould under pressure. A widely used method.

Rotational moulding - plastic material is heated in a slowly rotating, closed mould. This method can be used for moulding of large hollow objects.

Extrusion - another very widely used method. Molten plastic is extruded through a die, which gives it the required shape. If needed, other extensions to the process can be added, such as inflation of the extruded shapes into bottles.

Calendering- molten plastic is processed through a calender. It is pressed between two roll presses to produce sheet or film.

Thermoforming - heated and softened sheet of plastic is pulled onto or into a mould to give it a shape such as that of a bathtub.

Main European plastic consuming industries

Packaging Industry was responsible for 39.9 % of all EU plastics consumption in 2015. Such a large consumption is driven by the fact that plastic can be used in a large variety of packages (e.g. food film, hard plastic boxes, liquid-tight bags, various caps, bottles etc.), it is light, strong, easily coloured, transparent and easily sterilised. Plastic packaging help to reduce usage of preservatives in the food industry, extend shelf life and preserve the taste of food products. Transparent packaging allows customers to inspect the product without opening the packaging and desterilising the contents. Most of the plastic packaging can be recycled, therefore it is more environmentally friendly. While, packaging can be produced from many different types of thermoplastics, by far the most popular materials are polyethylene and polypropylene.

Construction Industry was responsible for 19.7 % of all EU plastics consumption in 2015. Plastics in this industry are used for insulation, pipe systems, window frames and interior design elements. Useful life of plastic pipes can exceed 100 years thanks to its rigidity and anticorrosive characteristics. More than half (by weight) of all new pipe installations are plastic pipes. Other plastic products in the industry are cable covers and protectors, walls, floors, roofs, tanks, insulation membranes. Main plastic used in this industry is polyvinylchloride (PVC), while the consumption of polycarbonate (PC), polystyrene (PS) and polyethylene (PE) is lower.

Automotive industry was responsible for 8.9 % of all EU plastics consumption in 2015. This industry values reliability, safety, resistance, lightness and ease of moulding and forming of a material. High strength and light plastics are perfect for exterior and interior vehicle parts (panels, handles, bumpers, lights). Lighter weight of plastic parts allows to significantly reduce total vehicle weight, therefore increasing fuel efficiency and reducing environmental impact. This industry uses polypropylene, polycarbonate, high-density polyethylene, acrylonitrile butadiene styrene and other technical or customised commodity thermoplastics.

Other large plastic consumers are electrical and electronics, agriculture, consumer goods, sports, homeware, furniture, protective gear industries. Characteristics that contributed to the popularity of plastics in packaging, construction and automotive industries make them just as applicable across a wider range of industries meaning that growth in demand for plastics is here to stay,

For more information, please contact us:

Phone: +370 5 2300426

Email: info@plastima.lt

| ↑ | ← |